High-Efficiency Compressed Air Dryers

DE iTECH energy-efficient refrigeration dryers ensure your compressed air meets the high standards of your products.

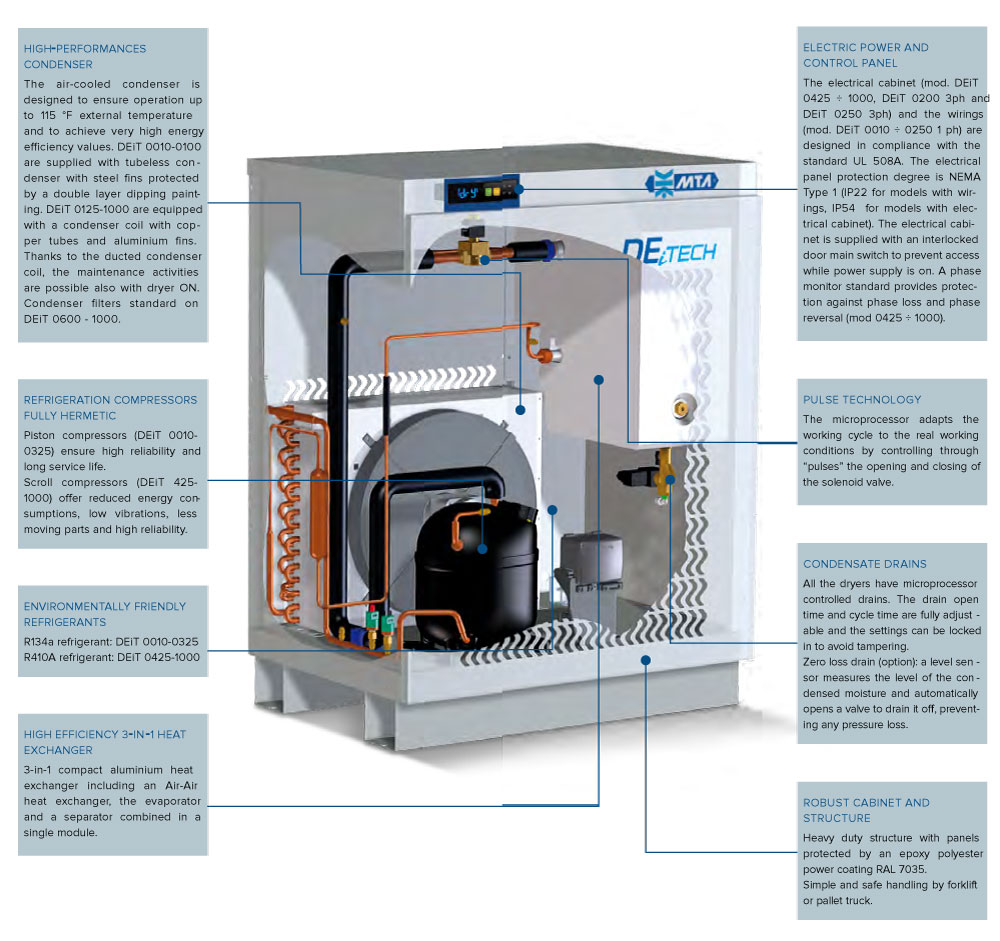

DE iTECH dryers use thermal storage and pulse operation to lower operating costs. In low-flow operation, the compressor cycles on and off to save energy. In medium and high-flow operation, the dryers use pulse technology to control the refrigerant flow to the compressor. The result is a nearly 33 percent reduction in operating costs and carbon dioxide emissions.

Standard Features

RELIABLE OPERATION

The simple refrigeration circuit, which does not utilize a hot gas bypass valve, and the careful engineering of materials and components, assure a long, trouble-free service life. The condenser coil is generously sized to maintain effciency in all environments, even at high ambient temperatures.

SERVICEABLE UNIT

A removable frontal panel assures easy access to the main refrigeration components, thus facilitating maintenance operations also with dryer ON. There is no need of seasonal adjustments (like adjustments required by hot gas by-pass dryers). Standard filters (DEiT 0600-1000) prevent mechanical equipment failure by stopping debris.

HEAVY-DUTY CONSTRUCTION

Heavy duty structure with panels protected by an epoxy polyester powder coating. The electrical panel (mod. DEiT 0425-1000, DEiT 0200 Three-Phase and DEiT 0250 Three-Phase) is designed in compliance with the UL 508A standard, with an IP54 protection against water and dust. The standard phase monitor provides protection against phase loss and phase reversal (mod 0425-1000).