Industrial Compressed Air Filters

Unfiltered and poorly filtered compressed air contains contaminants and particulate that may affect your process. With processes reaching higher levels of sophistication, compressed air networks also require higher purity.

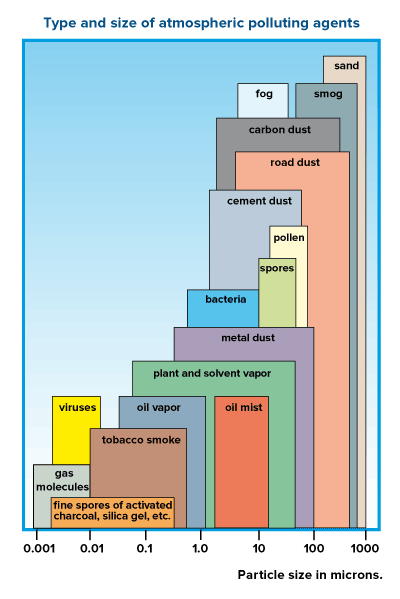

Atmospheric contamination found in air typically amounts to as much as 140 million particles per cubic meter. About 80 percent of these are smaller than 2 microns, and therefore pass through the air compressor’s air intake filter and into the compressed air network itself. When compressed to a pressure of 7 bar the number of particles contained in the compressed air reaches 1120 million per cubic meter.

Inadequate and low-efficiency filtration increases down time, raises maintenance costs and reduces process and product quality. MTA’s PureTec from Chillworx filters avoid these consequences, with guaranteed and lab-tested efficiency marks, with versions to meet all users’ needs.

Standard Styles

PURETEC HEF

The HEF range covers air flows from 1.0 to 46 cubic meters per minute. The extremely durable housing ensures years of trouble-free operation, whatever the conditions, thanks to standard anodization treatment. Numerous accessories simplify installation and operation, while the “CleanFit” design allows easy element substitution.

PURETEC B

Designed for higher air flows (46 to 150 cubic meters per minute), PureTec B filters feature a multi-element design offering maximum filtration surface area for lowest pressure drops within a compact housing. Element access is simplified thanks to the light-weight top access flange.

PURETEC HEF/50 and F

PureTec HEF/50 and F allow applications that require high pressure. The HEF/50 (2.9 to 32.2 m3/min) are made of aluminum and can operate up to a pressure of 50 bar. F filters (12.6 to 37.5 m3/min) are made of carbon steel and can operate at pressures up to 40 bar.